Outsourcing – More Complex Than Catchphrase

Obviously, on the surface, no one is against not preserving American jobs or better yet, not preserving high paying American jobs but beyond the catchphrase or politicspeak, it is a whole new world out there …

An interesting & insightful NY Times article on the business of business when it comes to outsourcing manufacturing and/or design work to other countries … the focus is on the iPhone but it does raises some deeper and more complex issues.

Some clips from the article that raise some interesting pros/cons to/fro in regards to the situation.

Apple employs 43,000 people in the United States and 20,000 overseas. An additional 700,000 people engineer, build and assemble iPads, iPhones and Apple’s other products. But almost none of them work in the United States. Instead, they work for foreign companies in Asia, Europe and elsewhere, at factories that almost all electronics designers rely upon to build their wares.

In 2007, a little over a month before the iPhone was scheduled to appear in stores, Mr. Jobs beckoned a handful of lieutenants into an office. For weeks, he had been carrying a prototype of the device in his pocket.

Mr. Jobs angrily held up his iPhone, angling it so everyone could see the dozens of tiny scratches marring its plastic screen, according to someone who attended the meeting. He then pulled his keys from his jeans.

People will carry this phone in their pocket, he said. People also carry their keys in their pocket. “I won’t sell a product that gets scratched,” he said tensely. The only solution was using unscratchable glass instead. “I want a glass screen, and I want it perfect in six weeks.”

After one executive left that meeting, he booked a flight to Shenzhen, China. If Mr. Jobs wanted perfect, there was nowhere else to go.

For over two years, the company had been working on a project — code-named Purple 2 — that presented the same questions at every turn: how do you completely reimagine the cellphone? And how do you design it at the highest quality — with an unscratchable screen, for instance — while also ensuring that millions can be manufactured quickly and inexpensively enough to earn a significant profit?

The answers, almost every time, were found outside the United States. Though components differ between versions, all iPhones contain hundreds of parts, an estimated 90 percent of which are manufactured abroad. Advanced semiconductors have come from Germany and Taiwan, memory from Korea and Japan, display panels and circuitry from Korea and Taiwan, chipsets from Europe and rare metals from Africa and Asia. And all of it is put together in China.

The impact of such advantages became obvious as soon as Mr. Jobs demanded glass screens in 2007.

For years, cellphone makers had avoided using glass because it required precision in cutting and grinding that was extremely difficult to achieve. Apple had already selected an American company, Corning Inc., to manufacture large panes of strengthened glass. But figuring out how to cut those panes into millions of iPhone screens required finding an empty cutting plant, hundreds of pieces of glass to use in experiments and an army of midlevel engineers. It would cost a fortune simply to prepare.

Then a bid for the work arrived from a Chinese factory.

When an Apple team visited, the Chinese plant’s owners were already constructing a new wing. “This is in case you give us the contract,” the manager said, according to a former Apple executive. The Chinese government had agreed to underwrite costs for numerous industries, and those subsidies had trickled down to the glass-cutting factory. It had a warehouse filled with glass samples available to Apple, free of charge. The owners made engineers available at almost no cost. They had built on-site dormitories so employees would be available 24 hours a day.

The Chinese plant got the job.

“The entire supply chain is in China now,” said another former high-ranking Apple executive. “You need a thousand rubber gaskets? That’s the factory next door. You need a million screws? That factory is a block away. You need that screw made a little bit different? It will take three hours.”

You can read the full article here.

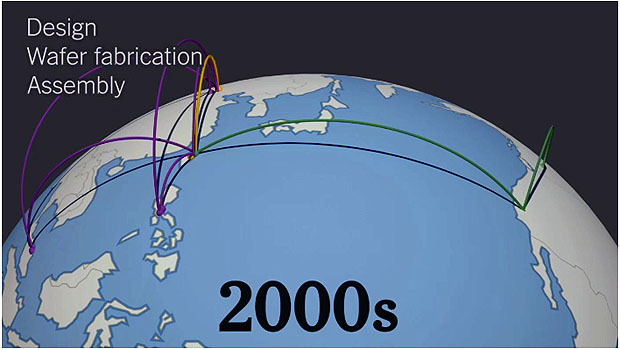

There is also a short animated video.

“The Chinese government had agreed to underwrite costs for numerous industries, and those subsidies had trickled down to the glass-cutting factory. It had a warehouse filled with glass samples available to Apple, free of charge. The owners made engineers available at almost no cost. They had built on-site dormitories so employees would be available 24 hours a day.”

This is part of what kills me about the outsourcing argument. The same folk that abhor government subsidizing anything are all to happy to buy “cheap” products that are cheap because of… government subsidy (as long as it is not their government doing the subsidizing). Also, maybe American companies could compete if they could afford to do free R&D and if their workers were “willing” to live in dormitories (slave quarters).

Who is willing to sign on to that?

It is unfortunate that the Land of the Free and the Home of the Brave relies on places that are anything but to provide us with the lifestyle we want.

Whatever they did, it doesn’t work. Those screens still scratch and break.

What annoys me more is the way companies who make these products don’t make anything to last. When the new I-phone’s come out, you can’t just update your old phone and get the new bits of hardware reassembled (i.e. the new processor and camera put it). Instead you have to buy a whole new phone. Sure you can update the OS but I am talking about the huge amounts of landfill that outdated technology makes. I know it would send these companies almost broke by not doing this, but imagine how better the world would be for it.

(MET: One thing in favor of the iPhone versus many other electronics, I have never gotten less than $225 for an old iPhone – or only about 25% depreciation after 1-2 years …).

OTOH, I’ve never paid more than $200 for a brand new BlackBerry, Droid, etc.

“The Chinese government had agreed to underwrite costs for numerous industries, and those subsidies had trickled down to the glass-cutting factory. It had a warehouse filled with glass samples available to Apple, free of charge. The owners made engineers available at almost no cost. They had built on-site dormitories so employees would be available 24 hours a day.”

This is part of what kills me about the outsourcing argument. The same folk that abhor government subsidizing anything are all to happy to buy “cheap” products that are cheap because of… government subsidy (as long as it is not their government doing the subsidizing). Also, maybe American companies could compete if they could afford to do free R&D and if their workers were “willing” to live in dormitories (slave quarters).

Who is willing to sign on to that?

It is unfortunate that the Land of the Free and the Home of the Brave relies on places that are anything but to provide us with the lifestyle we want.

China, India, Watch the worlds new superpowers, its all about cheap Labour!!

No it goes much deeper than cheap labor. Simply put the real rulers that control all international banks and corporations decided long ago that after a few more wars aimed at changing the system and controlling the affairs of the last few middle eastern countries (which needed to be new world order ready) there would no longer be a need for a strong middle class in America.

It’s just that simple. Things do not happen by accident. We are simply living through a script. That’s why there is seemingly so much hypocrisy in the world like having wars against communism but buying everything and having the Olympics in communist countries. In an honest world we wouldn’t buy anything from a communist regime.

Next up will be war with Iran with Israel heavily involved. This According to the writings of Zbigniew Brzezinski ( current adviser to Obama and formerly Carter) among others available for anyone that wants to read what’s really going on.

The truth is if the real powers that be wanted a strong middle class with plenty of good jobs available here they could keep America strong as long as they wanted but that’s not the plan so they won’t.

The cheap labor factories could not thrive without western countries buying their goods.

Met as far your statement that people want there to be good jobs available in America it’s simply not true. The people who control such things don’t want there to be an abundance of good manufacturing jobs in America. Otherwise there would be. Just like there was in the early and mid 1900’s when they still wanted a strong middle class in America. So there was.

Very interesting reading…

Neat…